In order to provide good service and make it convenient for communication, please select our sales representative according to your location, English or your mother language are both available.

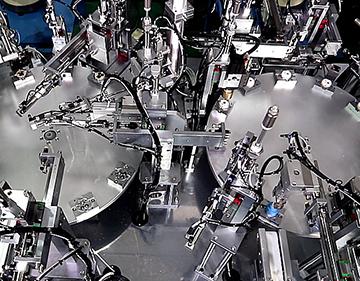

Complete Automation Solution:Concept---Design---Build

- Home

- Technology Modules

- Automation Test and Inspection Systems

Automation Test and Inspection System

- Automatic Vacuum Testing System

This is a module specially designed to prevent vacuum and water leakage in products.

- Vision Inspection Systems

Our automatic visual size and appearance inspection system is designed to check the tolerance of components or finished products in terms of position, direction, dimension, and shape.

- Go/No Go Gauge Measurement System

The go/no go gauge measurement system developed by NaiDe is a cost-effective inspection tool to check a workpiece against its allowed tolerances via a go/no go test.

- Defect Inspection Systems

Delays in delivery and interruptions because of defective products can be extremely frustrating and expensive. Luckily, the NaiDe defect inspection system can help alleviate these concerns.

- Automatic Feeding Inspection System

This system will accurately determine whether the product is properly loaded or not using a precision sensor.

- Automatic Assembly Inspection System

This inspection system is applied to your production line to ensure products are properly assembled.

- Automatic Defect Sorting System

This inspection system has a precision design concept and structure to distinguish between qualified and defective products.

- Automatic Size Inspection System

This inspection system is used to automatically measure a variety of size (height, diameter, symmetry, thickness, angle and relative position) dimensions of products with great accuracy.

- Automatic Current Detection System

According to your requirements, we can add a detection module to your production line to detect things like electrical leakage and voltage stability.