In order to provide good service and make it convenient for communication, please select our sales representative according to your location, English or your mother language are both available.

Complete Automation Solution:Concept---Design---Build

- Home

- Case Studies

- Sprayer Trigger Assembly Line

Sprayer Trigger Assembly Line

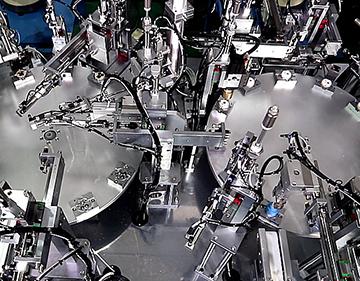

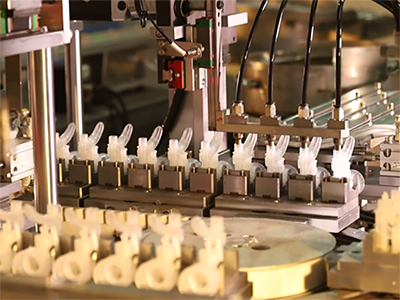

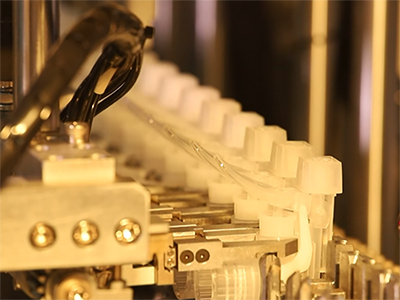

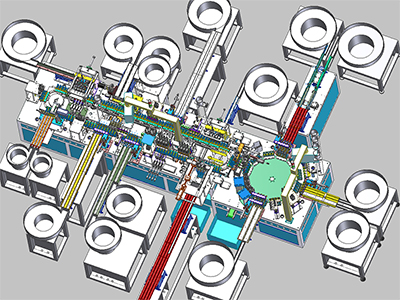

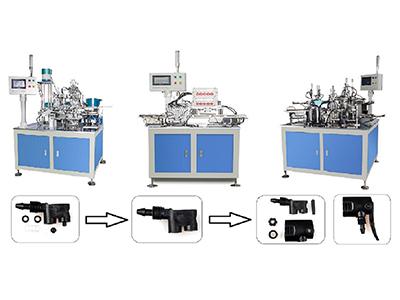

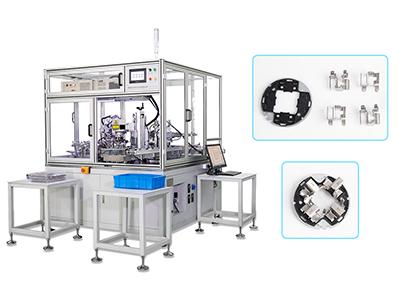

Our sprayer trigger assembly line is specially developed and manufactured for the plastic sprayer trigger bottles industry. This automatic assembly line combines assembling and gas tightness testing, realizing a higher assembly output. This trigger spray machinery can assemble and test 4 products at the same time. The production capacity of the machine has risen speedily, reaching more than 80 pcs per minute. The number of operators has been reduced from 13 to one, and the production capacity is far beyond the old assembly method. As a result, it greatly saves your labor costs and increases your productivity.

- The vibrating bowl delivers 4 parts at a time, with precise feeding in place, precise positioning of the machine, and synchronous induction detection after each product is in place.

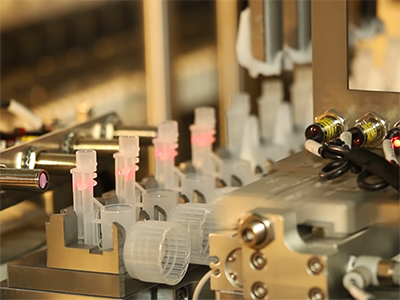

- The detection function runs through the process of product feeding and assembling to ensure that no parts are lost throughout the assembly and detection.

- The entire process of feeding, assembling, testing and discharging is carried out automatically and orderly, and the lotion pump is well assembled to ensure that there are no scratches, missing parts, oil stains, etc.

- Good products and defective products are sorted and separated, without mixing, once again improving the quality of customer benefits.

- The sprayer trigger assembly machine is equipped with counting function to ensure that customers can easily record weekly, monthly and annual output.

- The sprayer trigger assembly equipment is easy to operate, easy to maintain, and easy for operators to get started.

| Name | Full plastic sprayer trigger assembly line | Code | |

| Application | Sprayer | Working mode | Full-automatic |

| Size | Workspace | ||

| Weight | ≈750kg | Voltage | 220V/380V 50Hz |

| Power | ≈1.2kW | Capacity | 70-76 pcs/min |

| Display method | Human Machine Interface HIMI | Operator | 1 |

| PLC | Keyence/ | Relay | Omron |

| Touch panel | Weinview | Servo motor | ZhongDa |

| Air source treatment component | Festo | Linear Guides | Hiwin |

| External interface | RS232 | Sensor | Keyence |