In order to provide good service and make it convenient for communication, please select our sales representative according to your location, English or your mother language are both available.

Complete Automation Solution:Concept---Design---Build

- Home

- Case Studies

- Automotive High Pressure Oil Pump(hpop) Quick Connect Fitting Production Line

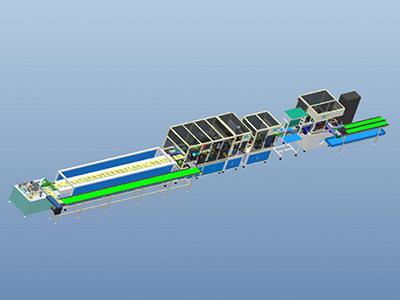

Automotive High Pressure Oil Pump(hpop) Quick Connect Fitting Production Line

The automated assembly and testing line is mainly used for assembly, cleaning, testing and packaging of connecting rod of engine.

Features

- Flaw detector inspects for cracks and defects in the product

- Special device to inspect the size for qualification

- Ultrasonic cleaner system to remove product impurities and stains, and dry the product

- Inner diameter inspection, automatically divided into 4 grades

- According to different grades the pin part will be matched for automatic riveting

- High pressure washing machine cleans away impurities and iron cuttings

- Automatic oil-sticking mechanism, mechanical structure has been treated with oil discharge corrosion

- Automatic and orderly packaging into the final product transfer tray without manual contact or alignment

- There is an NG port behind each inspection station

The whole line is steady operated by various automated assembly and testing machines. It can reduce the manual work to a minimum and elevate the productivity and product quality to a higher level.

Special Design

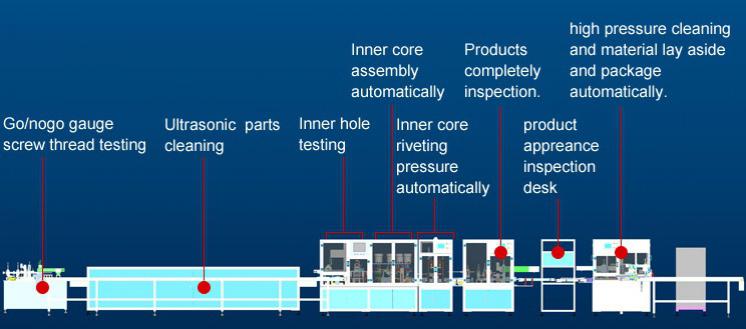

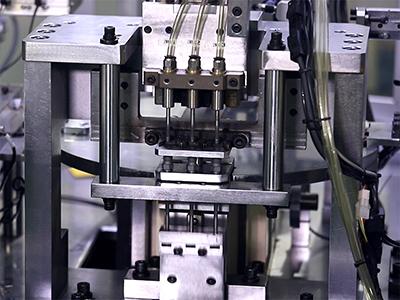

Our company has independently developed the go/no go gauge screw thread testing of our own. It can protect the screw thread surface with less chance of damage to parts in the inspection process.

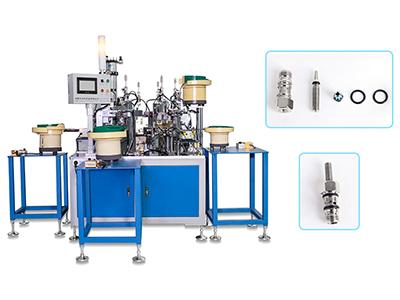

Hardness sorting machine and go/no go gauge testing machine: detecting heat treatment condition, avoiding material contamination and test product dimension

Hardness sorting machine and go/no go gauge testing machine: detecting heat treatment condition, avoiding material contamination and test product dimension Ultrasonic parts cleaning equipment: washing at high temperature, drying at high pressure, maintaining the constant temperature of product

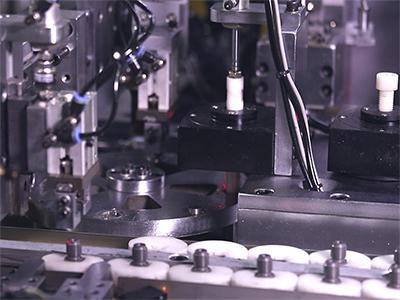

Ultrasonic parts cleaning equipment: washing at high temperature, drying at high pressure, maintaining the constant temperature of product Touch testing machine: automated measurement of inner diameter, inner ovality and relative height

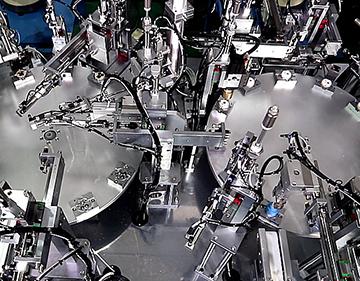

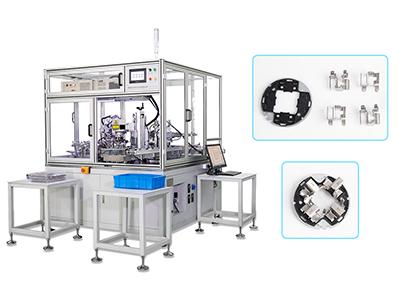

Touch testing machine: automated measurement of inner diameter, inner ovality and relative height Automated assembly machine: inner core riveting pressure automatically, press-fit depth detection

Automated assembly machine: inner core riveting pressure automatically, press-fit depth detection Complete product inspection: automated measurement of outer diameter, outer ovality, press-fit height and total height

Complete product inspection: automated measurement of outer diameter, outer ovality, press-fit height and total height Automated packaging equipment: automated discharging and palletizing

Automated packaging equipment: automated discharging and palletizing

Specifications

- Voltage: 240V 50HZ

- Pressure: 0.4-0.6Mpa

- Power: 1-2KW

- Dimension: 18000*1200*1500mm

- Capacity: 20 pieces/min

Contact us for more details and video information.