In order to provide good service and make it convenient for communication, please select our sales representative according to your location, English or your mother language are both available.

Inquiry Form

Professional automation machinery builder,

Complete Automation Solution:Concept---Design---Build

Complete Automation Solution:Concept---Design---Build

Custom Automation Solutions

- Home

- Case Studies

- Mixed Water Ceramic Valve Core Automatic Assembly and Vacuum Inspection Line

Mixed water ceramic valve core automatic assembly + vacuum inspection line

Application

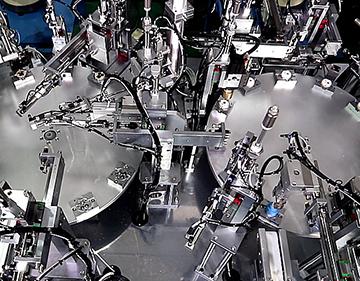

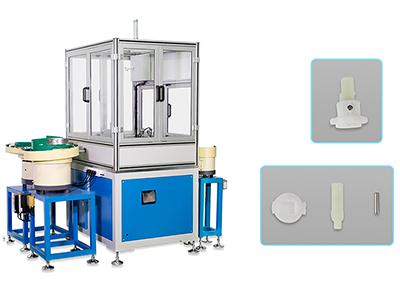

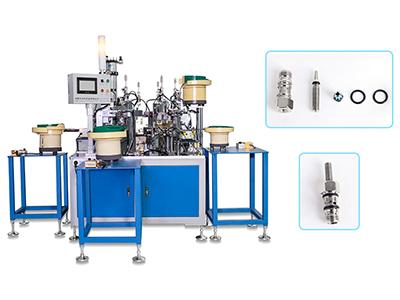

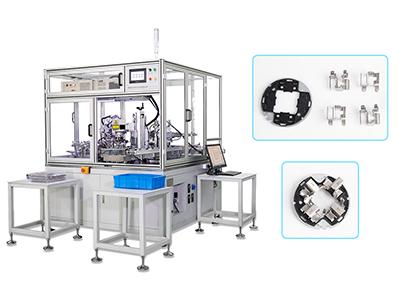

Composed of three machines in the following, our automated production machinery is designed for automated assembly and leak testing of mixer tap valve.

Details

Specifications

- Measurement Range: <1MPa

- Measurement Resolution: 0.001MPa

- Measurement Tolerance: 0.004MPa (slight difference between varying workpieces)

- Power: 1-2KW

-

Assembly Machine Features

- Fully automatic or semi-automatic feeding method are both used in one machine

- Various items can be assembled

- Automatic oil filling, oil evening function

- Control the amount of oil filling, minimize the loss of consumables and reduce the product defect rate

- Automatic sorting direction controlled by a visual system for irregularly shaped samples

- Viscous products are automatically dispensed to prevent mixing

- Reduce labor costs while increasing production capacity and qualification rate

-

Vacuum Testing Machine Features

- Can be used as a single machine or connected to an assembly machine to form a production line.

- Every process has uniform oil function

- 5 products can be tested simultaneously

- Pressure is applied for 8 seconds during each process

- Automatic and repeated hot and cold water direction opening and closing test method, this ensures vacuum detection is more reliable

- The automatic product shell vacuum test method can detect the quality of the inside of ceramic pieces to ensure that the product qualification rate exceeds 99.8%.

Please contact us for more details and video information.

Related Product